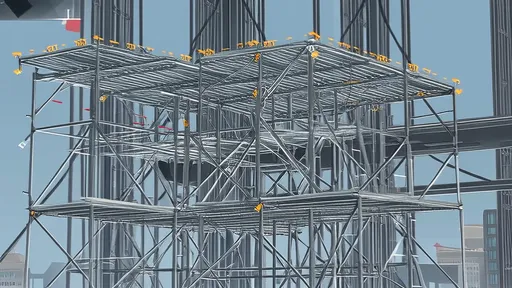

In the realm of construction engineering, the stability of temporary support systems remains a critical yet often underestimated aspect of project safety and efficiency. Scaffolding structures, which provide essential access and support during building, renovation, and maintenance work, demand rigorous attention to design, calculation, and implementation. The consequences of oversight can be catastrophic, leading to structural failures, injuries, and significant financial losses. As such, a deep understanding of the principles governing scaffold stability is not just a regulatory requirement but a moral imperative for engineers and site managers alike.

The foundation of any stable scaffolding system lies in its structural design, which must account for a multitude of dynamic and static loads. These include the weight of materials, workers, equipment, and environmental factors such as wind, snow, or seismic activity. Engineers employ advanced computational models to simulate these conditions, ensuring that the scaffold can withstand anticipated stresses without deformation or collapse. Key to this process is the application of finite element analysis (FEA), which allows for precise modeling of load distribution and stress points across the entire structure.

Material selection plays an equally pivotal role in determining the integrity of temporary support systems. High-strength steel and aluminum alloys are commonly used for their favorable strength-to-weight ratios and durability. However, the choice of material must align with the specific requirements of the project, including corrosion resistance, ease of assembly, and compatibility with other structural components. Additionally, the quality of connectors, couplers, and base plates cannot be overlooked, as these elements are often the weakest links in the system if not properly manufactured and installed.

Another crucial factor in scaffold stability is the geotechnical consideration of the ground or surface on which the structure is erected. Uneven or unstable terrain can compromise the entire system, leading to tilting or sinking. Site assessments must be conducted to evaluate soil bearing capacity, drainage conditions, and potential subsidence. In cases where the ground is inadequate, measures such as the use of base plates, mudsills, or even temporary foundations may be necessary to distribute loads evenly and prevent displacement.

The human element cannot be ignored when discussing the stability of scaffolding systems. Even the most meticulously designed structure can fail if assembled, used, or maintained improperly. Training and certification for scaffold erectors and users are essential to ensure that best practices are followed. This includes adherence to manufacturer guidelines, regular inspections for signs of wear or damage, and immediate corrective actions when issues are identified. Furthermore, communication between design engineers, site supervisors, and construction teams is vital to address any on-site challenges that may arise.

Regulatory frameworks and standards provide a necessary baseline for scaffold safety, but they should be viewed as the minimum requirement rather than the ultimate goal. Organizations such as OSHA in the United States, EN standards in Europe, and similar bodies worldwide establish guidelines for design loads, safety factors, and inspection protocols. However, forward-thinking companies often exceed these standards by implementing more rigorous internal checks, utilizing real-time monitoring technologies, and fostering a culture of safety that prioritizes proactive risk management over reactive compliance.

Technological advancements are revolutionizing the way scaffolding stability is calculated and monitored. The integration of IoT sensors allows for continuous tracking of load conditions, environmental changes, and structural movements. Data collected from these sensors can be analyzed using machine learning algorithms to predict potential failures before they occur, enabling preemptive interventions. Additionally, Building Information Modeling (BIM) software facilitates collaborative design and visualization, helping stakeholders identify and resolve stability issues during the planning phase rather than on-site.

Despite these advancements, challenges persist in ensuring universal adherence to stability protocols. In many regions, especially in developing economies, the use of non-standardized or substandard materials remains prevalent. Economic pressures sometimes lead to shortcuts in design or installation, increasing the risk of accidents. Addressing these issues requires not only stricter enforcement of regulations but also greater investment in education and resources for smaller contractors who may lack access to advanced tools or expertise.

Looking ahead, the future of scaffold stability calculation lies in the further integration of digital twins—virtual replicas of physical systems that can be used for simulation and analysis. By creating a digital twin of a scaffolding structure, engineers can test various scenarios and optimize designs in a risk-free environment. This approach, combined with augmented reality (AR) for on-site guidance during assembly, has the potential to significantly reduce errors and enhance overall safety.

In conclusion, the stability of scaffolding and temporary support systems is a multifaceted issue that demands a holistic approach. It intertwines engineering precision, material science, geotechnical understanding, human factors, regulatory compliance, and technological innovation. As construction projects grow in scale and complexity, the industry must continue to evolve its practices, leveraging new tools and methodologies to ensure that these temporary structures remain steadfast under all conditions. The goal is not merely to prevent failures but to create environments where workers can perform their duties with confidence, knowing that their safety has been meticulously calculated and assured.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025